Lean Blog Archive

Want to learn more about Lean and Continuous Improvement? Subscribe to the Lean Listserv by sending an email request to leancoach@uthsc.edu!

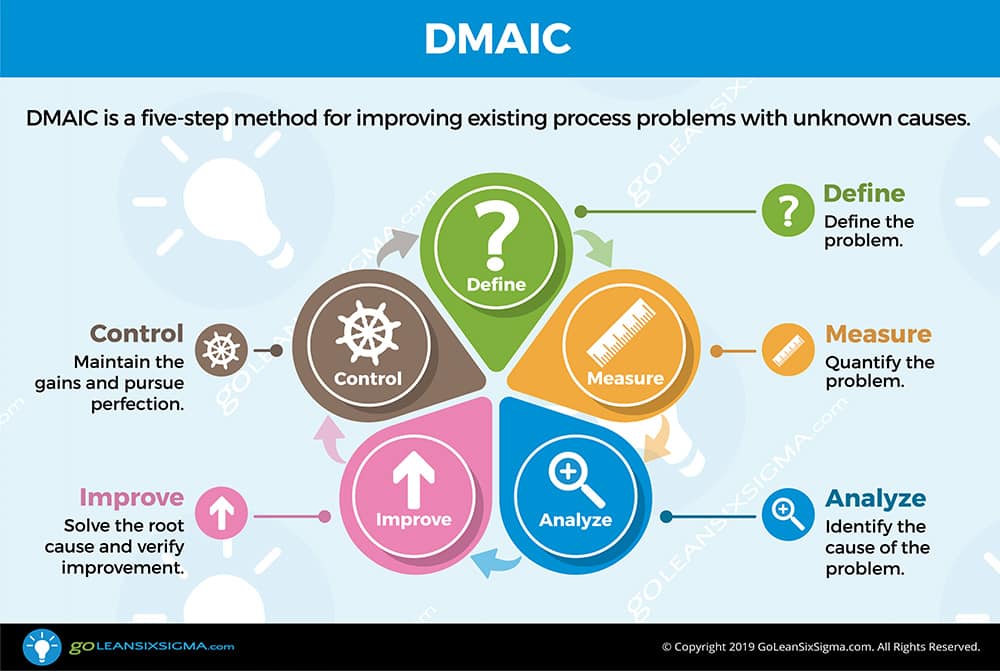

You’ve gone through every phase of DMAIC except the last one – it isn’t that important, is it? YES! Control is super important because if you don’t make sure you control the process, the chances are that it won’t be sustained, and then you are back to square one.

Make sure you keep your new process running smoothly with hints from this Control – Phase 5 (of 5) of Lean Six Sigma article.

Have a problem you need help solving? Reach out to the Lean team for support by emailing us at lean-coach@uthsc.edu.

Believe it or not, this is the fun part. Now you get to brainstorm with co-workers on how to improve your process. It may seem a bit painful at first, but in the end, you will make the process so much better and easier than ever!

Read this GoLeanSixSigma article that goes into greater detail about the Improve phase.

Have a problem you need help solving? Reach out to the Lean team for support by emailing us at lean-coach@uthsc.edu.

You’ve defined your problem, measured your problem, and now, it is time to analyze it.

Take a few minutes to read GoLeanSixSigma’s Analyze – Phase 3 (of 5) of Lean Six Sigma article.

Have a problem you need help solving? Reach out to the Lean team for support by emailing us at lean-coach@uthsc.edu.

You’ve defined the problem – now what? You have to measure what is currently going on. Why? Because if you don’t measure your current process, you have nothing to compare your improved process against! Learn more about the Measure phase through this GoLeanSixSigma article.

Have a problem you need help solving? Reach out to the Lean team for support by emailing us at lean-coach@uthsc.edu.

Last week, we sent a brief description of the five steps of DMAIC.

This week, this quick GoLeanSixSigma read tells you everything you need to know about the Define phase. You have to define the problem before you can even begin understanding how to solve it.

Have a problem you need help solving? Reach out to the Lean team for support by emailing us at lean-coach@uthsc.edu.

GoLeanSixSigma defines DMAIC as “the problem-solving approach that drives Lean Six Sigma.” And it is pronounced “duh-may-ik,” but don’t let the “ik” part deter you. DMAIC is a great way to approach a problem – not matter what the size!

This email has a link to GoLeanSixSigma that briefly defines each phase. Then each week for the next five weeks, we will send out a link that dives a little deeper into each phase.

Have a problem you need help solving? Reach out to the Lean team for support by emailing us at lean-coach@uthsc.edu.

(04/07/22)

Did you know there are an estimated 55 million meeting each day in the US? As Pinkcast says, "Meetings stink." But what if they didn't have to? What if meetings could be more productive and take less time? Check out this quick 2:35 minute video and learn about Separate, Stand, and Shrink.

(03/04/22)

Do you want to learn more about Lean, but you don’t have time to take a class, read a book, or watch a video?

Check out the Lean Six Sigma Bursts podcast by Brion Hurley. We know Brion – he is the master black belt that assisted us in getting our green belts.

In 5 minutes or less, Brion gives you rapid improvement ideas, and you can leave a voicemail message to have your questions answered in a future episode.

Episode 50 is “Lean at Home,” a brief introduction to a free course that helps you learn Lean by making your home life more efficient. Once you begin using Lean at home, you start to see how Lean can help at the office.

Ruth Archer is the director of Continuous Improvement at Michigan Technological University, a member of the Lean HE Steering Group, and a true Lean Rockstar.

She recently sent out the following email about the free Lean Higher Ed (HE) Quick Takes meeting – three speakers, 15 minutes, and lots of opportunity for learning:

Please take a moment to register for the Lean Higher Ed (HE) Quick Takes next Tuesday, Feb 15, 4-5 PM ET. The purpose of these quick takes is to educate our Lean higher ed community on Lean culture, principles, processes, methods, and tools as they are applied at universities and colleges. Participation is free!

We will have 3 speakers at this event. You can read about two of them below, and the third will be a surprise! Each topic will have 15 minutes--10 minutes for presenting and 5 minutes for questions.

- Topic: Print Optimization Improvement Project, Part 2 -- Ongoing Measurement and Lessons

Learned

Presenter: Ray Konecsni, Director of IS Client Services at the University of Regina, Canada

Description: The University of Regina ran a successful improvement project to optimize printers by reducing the number of personal printers and moving to a shared print network, saving the university $4.4 million dollars. They used data to identify the opportunity and combined process improvement, enterprise business process

management, and change management to achieve their success. - Topic: Virtual PIEs - Lessons Learned

Presenter: Rebeccah Cusick, Institutional Effectiveness Coordinator, Northwood Technical College

Description: We knew shortly after we went remote in March 2020 that we would need to move our Process Improvement Events (PIEs) to a 100% virtual platform. Our approach included pulling together a taskforce of current process improvement facilitators to brainstorm moving all activities to a virtual environment thru Microsoft Teams, research virtual whiteboard tools, and reimagine how to engage PIE participants in a virtual environment. This included being flexible in length of days and # of hours for each event.

Register here; a meeting invitation will be sent to you after registration is complete.

Want to submit a proposal for a future Lean HE Quick Takes event? It's easy! Please fill out this form: https://forms.gle/kDBcwHNPSoFH1So67

Let me know what questions you have!

Have a fabulous day,

Ruth

Happy New Year! After a brief hiatus, we are back with this inspiring article about how Tacoma Public Schools reduced new employee setup time by 80%.

80%!

How did they do it? By asking every school district to strive to:

- Reduce waste

- Streamline processes

- Build a culture of problem solvers

It may seem complicated to get started with taking a deep dive into your work processes and thinking about what can be done to improve them. But wouldn’t you like to get 80% of a task time back?

80%!

Watch this video to learn more about how Tacoma Public Schools made lean work for them!

Document your processes, document your processes, document your processes. You probably tire of us saying that repeatedly, but documenting processes is a vital way to prevent tribal knowledge.

Tribal knowledge happens when an entire process or essential process information resides only in an employee’s mind and poses a potential danger to your work and productivity. What if that person is out sick or quits? Important information or the process itself could be lost forever.

How do you prevent tribal knowledge from happening in your area? Ensure work is as standardized as possible (two people are doing the same job do it the same way), and all processes are documented. Just writing the steps down on a sheet of paper is a simple way to start!

ISixSigma has an excellent article about tribal knowledge . Even though the example given is about an assembly line, it is easy to understand what tribal knowledge is and the best ways to avoid it (cross-training, anyone?).

“I don’t have time to improve my processes.” We hear it all the time.

But it’s essential to regularly set aside time to concentrate on improvement, even when you feel like you don’t have any time to spare.

Why?

Because if you don’t spend a little time focusing on improvement, you will continue to spend much of your time putting out fires.

(from The Loop for State of Tennessee) Usually when you hear about productivity, it’s in reference to work. However, personal productivity is a real thing too and you may find that personal and work productivity feed off each other. From knocking out your to-do list to embarking on personal goals, productivity is a necessary and important quality to have.

Check out 5 tips for improving your personal productivity to accomplish more (and most are also applicable to work productivity):

Do What You Love

To make yourself the most personally productive person you can be, set and work toward goals that are consistent with your values and hobbies. For example, if you’re setting a goal to be more active, focus on activities you already enjoy. Don’t attempt to force yourself into things you’ll dread or put off. Instead, pick out options you feel excited about. For the smaller (and less enticing) tasks, like chores around the home, tie it to something you still enjoy. Put on your favorite album or a great TV show you can listen to in the background while you work. This will make the work itself much easier and more enjoyable.

Don’t Be Afraid to Fail

Setting goals is the easy part. Following through on them is where you need to tap into your motivations and personal productivity. Many struggle to get started on their tasks and goals because they worry about failing. But remember—failure is not only a normal part of life but is also extremely important in your personal growth. Failing simply means you tried, and it didn’t go the way you hoped. Next time, shake it off and use your previous mistakes to map out a new plan for success.

Tap Into High Energy Days

We all have those days where we wake up feeling like we can accomplish anything. When you come across one of those days, tap into it! Break out your to-do list and take advantage of your higher energy to cross off some tasks. If you’ve got a goal in mind, use this energy to start taking steps towards accomplishing it. On the flip side, understand and accept that some of our days are lower energy than others, and that’s okay! Give yourself permission to take a break and relax so you can build your energy back up once more.

Communicate

Communication at work is key. It’s how your colleagues and managers understand where you are in a project, what tasks you’ve completed, and where you’re needing assistance. Bring that work communication mindset into your personal life too. Tell family and friends about your personal goals, or simply what you’re hoping to accomplish that day! By communicating, you’re both creating a community of supporters and you’re also making yourself more accountable, thus encouraging you to keep working towards your goals.

Cheer Yourself On

At work, we are often recognized and rewarded for our hard work and exciting accomplishments. When it comes to personal goals and tasks, there’s no boss or colleagues to give you a pat on the back. But that just means it’s up to you! Accomplishing goals is something to be excited about, so work on becoming your own cheerleader and celebrate your successes in a way that feels both personal and meaningful. Then, as you continue setting new goals, you’ll know what you’ve got to look forward to!

There’s no reason our high levels of work productivity shouldn’t translate to our personal lives. Just like you set high standards and exciting work-related goals for yourself, bring this mindset and productivity to the table when you’re working through your to-do list or setting goals for yourself.

Even the best of us get distracted during meetings. How should you handle it if you are a facilitator?

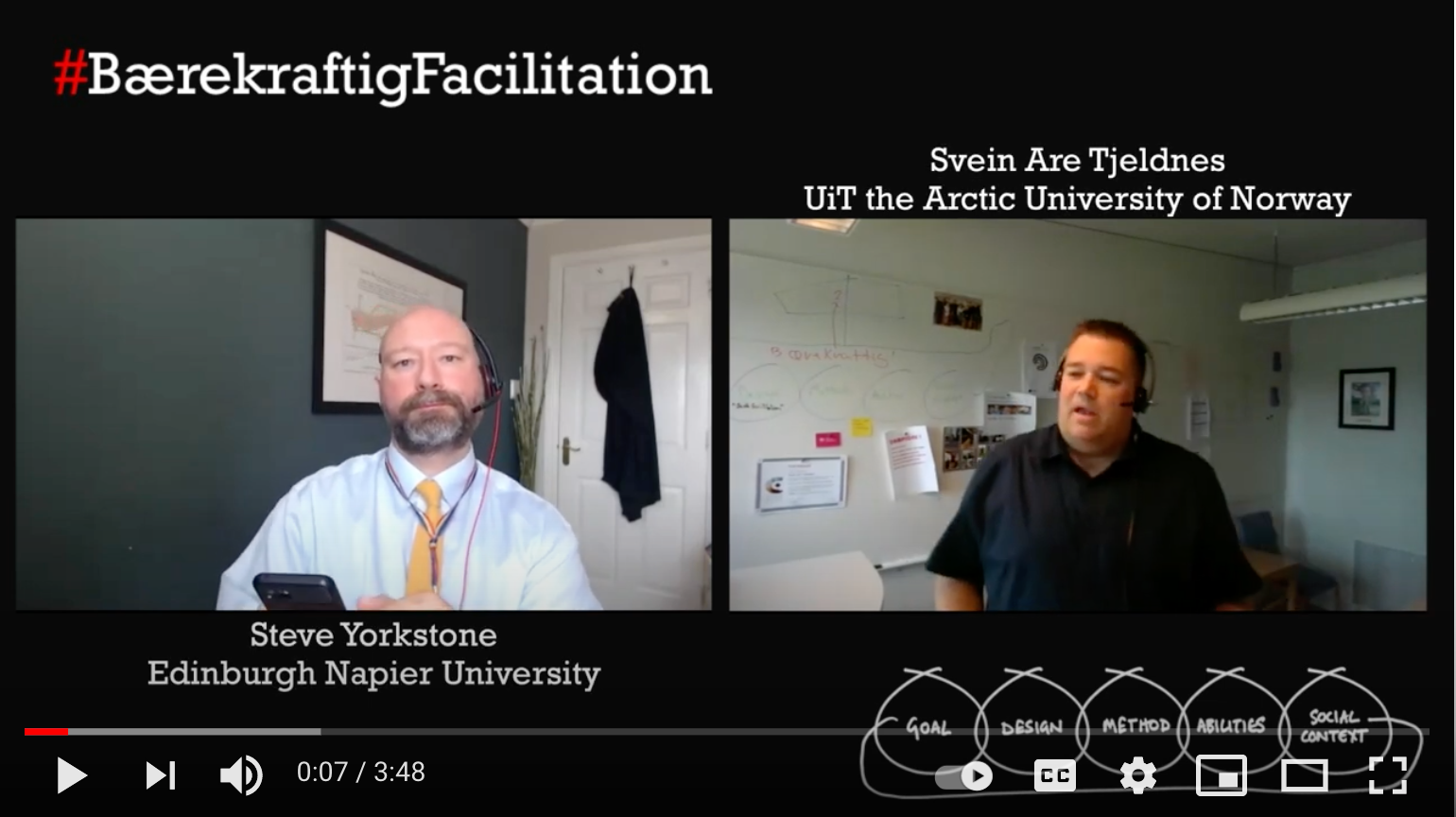

Our Lean HE friends, Svein Are Tjeldnes (UiT the Arctic University of Norway) and Steve Yorkstone (Edinburgh Napier University) have put together a 3-minute BærekraftigFacilitation video giving you some excellent suggestions.

p.s. Bærekraftig is Norwegian for “sustainability.” Where else can you learn a little

about Lean and little Norwegian all in one email? Hadet!

p.s. Bærekraftig is Norwegian for “sustainability.” Where else can you learn a little

about Lean and little Norwegian all in one email? Hadet!

The 2021 NCCI Annual Conference had some fantastic sessions! Unfortunately, even we missed sessions because we were working hard on getting UTHSC TechConnect ready for you.

But there is good news – if you registered, session recordings, related materials, and slides are available online to all those who registered for the conference via NCCI Connect in our Conference Library.

If you couldn’t register to attend the live conference, you could still register to view the excellent content! Individuals whose institutions registered for unlimited attendance (that’s us!) can register for free access to the recordings. If you watch the opening keynote, you will notice UTHSC won the Ron Coley Award (which is why anyone with a UTHSC email got to attend the conference for free).

Have you ever led a meeting where things just completely went off the rails? You scheduled an hour to knock out three or four things, and someone went on a tangent, usually because they genuinely wanted their voice to be heard.

The problem is, if you don’t recognize their idea, many people will keep bringing the conversation back to it. So now you have lost complete control, and the meeting is unproductive.

Enter Lean’s beloved Parking Lot. A parking lot helps you recognize everyone’s ideas by placing them in an area (usually on a whiteboard or in meeting notes), so you can discuss these ideas in a future meeting. Sure, it is a bit of a meeting deflection tactic, but it helps keep the discussion focused on completing your scheduled tasks.

And, many ideas that come to people in meetings ARE relevant and helpful, so you want to record them. A parking lot helps you keep control of your meeting while also recognizing ideas to be addressed later.

Learn more about the parking lot and how to use it to your advantage in meetings by reading Quick and Dirty Tips’ How to Use the ‘Idea Parking Lot’ in 4 Simple Steps article.

Merriam-Webster’s defines clarity as the quality or state of being clear. Is your work process clear? Or are there some fuzzy areas that could use some work?

Karen Martin, president of TKMG Academy, has developed a webinar titled Clarity: The Essence of Lean Management. She finds clarity a necessity for successfully deploying lean management.

If you have an hour to spare, register online to immediately view the webinar.

As Process Palooza 2021 begins to winds down, this is just a quick reminder that you can view recordings of any sessions you missed.

Just go to the UCSD website, look on the left under the Process Palooza 2021 title, and click on the session you would like to see.

And, remember to share the word that UTHSC can attend the 2021 NCCI Annual Conference, held virtually on July 21-22 for free. Simply visit the registration site, log in or create a new account, and then register with your UTHSC email.

We often overlook it, but continuous improvement surrounds us! If you think about

day-to-day activities, you realize that without CI, many things in our lives would

be much different.

We often overlook it, but continuous improvement surrounds us! If you think about

day-to-day activities, you realize that without CI, many things in our lives would

be much different.

Some improvements are just simple audio reminders of things we need to do. Here are examples of how things would change if someone at a company had not once said, “What if we…”

- The credit card machine sound it makes after charging you reminds you to remove your card (instead of getting distracted and leaving the card behind).

- The concrete barrier at the end of a parking space prevents you from pulling up too far (or stops you from running into a building if you accidentally press the gas instead of the brake).

- Car notification reminds you when the oil needs to be changed (instead of you trying to remember the date).

- The sound the car makes when you forget to buckle your seatbelt (instead of letting you ride around unprotected).

- The solar-powered speed limit sign that posts your speed (so you know to slow down, if needed).

- The sound the oven makes when it reaches the preheat temperature (so you don’t have to check the oven several times to make sure it was at the correct temperature).

- The sound the phone makes to notify you when you receive a text (so you don’t have to just randomly check every so often for a message).

- The clock on your coffee pot you set to automatically brew the coffee (so it’s ready as soon as you wake up).

- The snooze button on your alarm clock (to give you that extra 10 minutes of sleep).

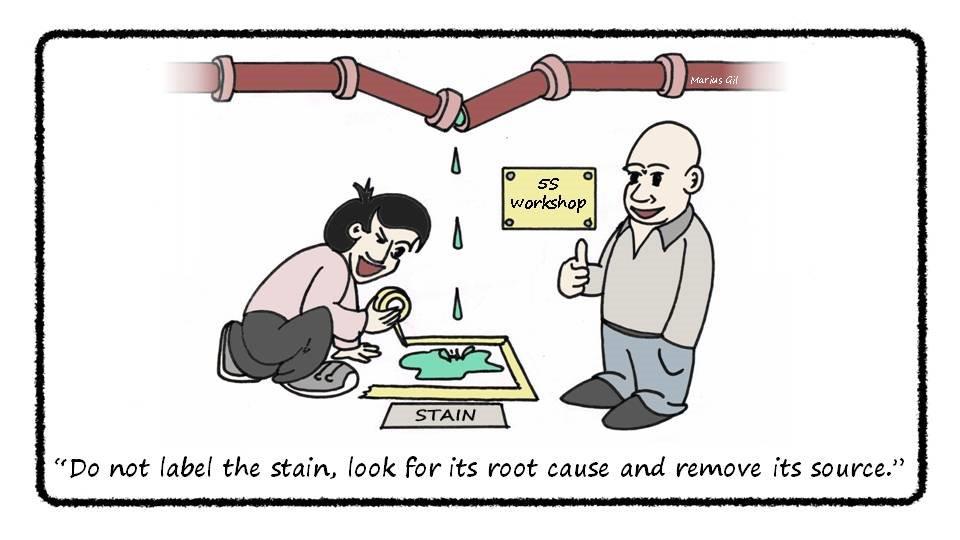

It’s been a hectic week and I’ve been searching for something profound to talk about…then, I remembered a picture is worth a thousand words.

Got a problem? Look for the root cause and remove its source.

It’s been a full year of Zoom/Teams meetings, but you may still feel like you don’t have a good grasp for online meeting facilitation. Even as things are getting better, we all still struggling at times.

Our Lean HE friends, Svein Are Tjeldnes (UiT the Arctic University of Norway) and Steve Yorkstone (Edinburgh Napier University) have put together a 3-minute Bærekraftig facilitation video about judging how a group is feeling during an online meeting.

p.s. Bærekraftig is Norwegian for “sustainability.” Where else can you learn a little about Lean and little Norwegian all in one email? Hadet!

This is an awesome interview GoLeanSixSigma did with Cecilia Martinez, an Assistant Professor of Engineering & Management at Clarkson University. She is a Lean 6 Sigma master black belt who has worked in the automobile and electronics industries. In this interview, she talks about how Lean 6 Sigma can be used successfully in higher ed.

Do you feel you are serving a purpose with your job? Or, if you are a leader, does

your staff know what purpose they are serving?

Do you feel you are serving a purpose with your job? Or, if you are a leader, does

your staff know what purpose they are serving?

Or, does everyone just have a “do your job and clock out” mentality?

Each day, we are all helping to create doctors, nurses, dentists, audiologists, pharmacists, occupational therapists, researchers, and other healthcare professionals. But, do any of us ever come to work with that mentality?

Have you heard the parable of Christopher Wren and the bricklayers?

Christopher Wren was a famous 18th century architect who was commissioned to rebuild St. Paul’s Cathedral after the great London fire.

One day while at the cathedral, Wren noticed three bricklayers on a scaffold, all intently working on their craft. Wren approached each man individually and asked the same question, “What are you doing?”

The first man responded that he was a bricklayer and he was working hard so he could feed his family.

The second man replied that he was a builder and was building a wall.

But, when Wren asked the third man what he was doing, he got an entirely different answer. “I am a cathedral builder. I am building a great cathedral to The Almighty.”

Now all three men were doing great work, but number three was the hardest worker and later promoted to leader. Why? Because he felt a great purpose in his work.

When you feel your work is contributing to something important, say creating a better healthcare system, you care more about your job. You realize the importance of the end result and are motivated to make sure your work is the best it can be.

This all goes back to the university’s mission statement – “to improve the health and well-being of Tennesseans and the global community by fostering integrated, collaborative, and inclusive education, research, scientific discovery, clinical care, and public service.”

So, next time you are working on a form for admissions or fixing code in a database or answering the phone for a department, remember that your job is helping to improve the health and well-being of Tennesseans. No matter how big or small you think your job is, you are making a difference in the lives of others.

One thing lean practitioners love to do is network. There’s a good reason for this – when you connect with more lean practitioners, you learn new concepts and ideas. I attended a 30 minutes lean coffee chat today and came away with three URLs to visit and a new LinkedIn group to join!

Here are some lean groups in LinkedIn that you might be interested in joining. If you are not a member of LinkedIn, you can join for free.

Don’t worry about your level of “leanness” – I mostly just set back, read, and absorb the knowledge of others.

This time a year ago, we had just completed a couple of successful Process Map courses

and were ready to expand our Lean training.

This time a year ago, we had just completed a couple of successful Process Map courses

and were ready to expand our Lean training.

Then, COVID changed everything.

Since then, we’ve tried to spread the Lean word through our website and these listserv emails, but what options are out there if you want Lean 6 Sigma training?

GoLeanSixSigma has a quick and free one-hour White Belt training available. The lean coaches took their yellow belt training a few years back and it was very easy to learn. There is also free white belt training at SixSigmaOnline, but we haven’t taken this course, so we can’t vouch for it.

There are some great, no cost to you resources on LinkedIn Learning. First, log into our portal at https://linkedinlearning.utk.edu/ to get full access. Duo authentication may be required and if you have a LinkedIn account, you may be asked to log in to that as well. Once you are in the website, search for Lean 6 Sigma to find videos that are as short as 3 minutes to courses that last an hour or longer.

And, of course, if you ever have any questions about lean, process mapping, continuous improvement, etc., please reach out to us at leancoach@uthsc.edu.

Continuous Improvement – CI – why bother?

Christopher Chapman tells you in 5 words (and only 8 minutes). So check out this video for inspiration as to why we should be concerned about CI.

One of the habits taught in the 7 Habits of Highly Effective People course is to Sharpen

the Saw. That just means to take some time to work on your greatest asset – you! What

better way to do this than to take some time to learn something new.

One of the habits taught in the 7 Habits of Highly Effective People course is to Sharpen

the Saw. That just means to take some time to work on your greatest asset – you! What

better way to do this than to take some time to learn something new.

We have an awesome resource – LinkedIn Learning – where you can learn all types of things at no cost to you.

If you are interested in learning more about process improvement, LinkedIn Learning has a course taught by writer and keynote speaker Chris Croft. It’s self-paced and you can add it to your LinkedIn profile once you’ve finished the course.

To access the course:

- Login to UTHSC’s LinkedIn Learning site (NetID/password required).

- Go to the Process Improvement Foundations course.

Most everyone has a process that is not working quite as well as it should be. If

you don’t, you are our hero!

Most everyone has a process that is not working quite as well as it should be. If

you don’t, you are our hero!

Many times, we are so anxious to solve a problem, we immediately want to jump to the solution.

When you notice something not working smoothly, write down what is happening. Try to avoid quickly jumping to, “What is the solution?”

Instead, ask yourself and coworkers questions like, “Why is this happening?” “Where is the bottleneck?” and “Could we be doing this a different way?”

Ask someone outside the process for their input. Sometimes they can see things we cannot because we are too close to the process.

If you don’t give the problem the proper consideration, you aren’t really “solving” anything except the rapidly perceived problem. The real problem may still there until you give it more careful thought.

2021 is right around the corner. Did you make any resolutions? An easy one to make and keep is to be more productive.

And, we have the perfect way to help you keep that resolution! Check out our newly launched Productivity and Collaboration webpage. We have instructions, articles, videos, FAQs, and tips.

The more you know about the tools ITS has to offer, the more productive you can be!

Don’t see something you want to learn more about? Let us know at leancoach@uthsc.edu.

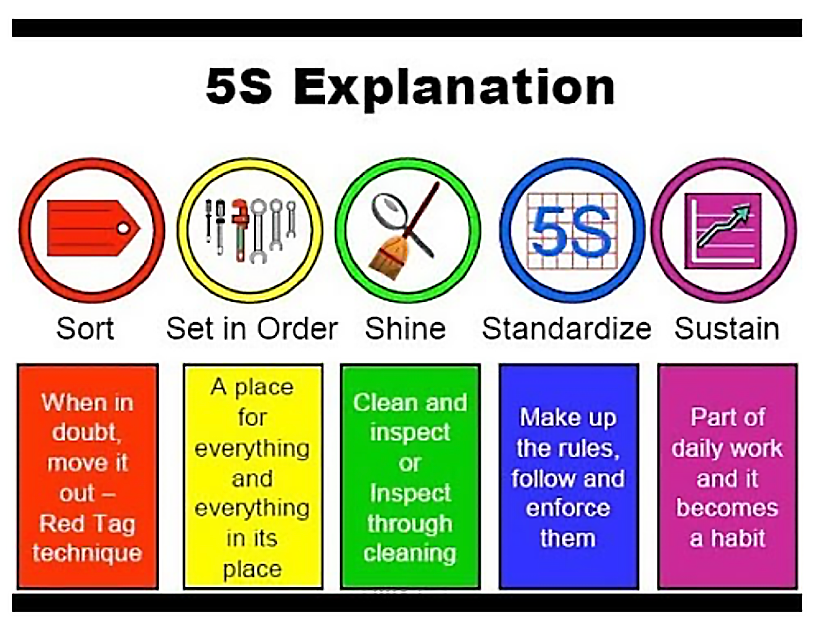

We’ve talked about using the 5S method to organize your office, but what about your files and documents?

We are encouraging users to move off older servers such as Isilon My Drive or Volshare, but where do you start? With 5S!

5S is a Japanese method used for organizing things. The 5Ss are seiri, seiton, seisō, seiketsu and shitsuke. These have been translated into:

- Sort: Sort through your files and remove anything unnecessary. Start looking at documents on your hard drive and cloud storage. Start with the oldest files. Do you still need that file from 2014 about a process that you no longer use? No? Delete it. Unsure as to whether you will need something or not? Back it up then delete.

- Set in Order: Put all necessary items in the optimal place. Use your folders to help keep files organized so you can find them when you need them. Give the folders easy-to-identify names so you know exactly what is in each folder.

- Shine: Sweep, clean, and inspect your file storage on a regular basis. Set aside a regular time (weekly, biweekly, or monthly) to look through your hard drive and cloud storage for items that can be deleted. Once you make the initial run through, it should be quick and easy to “shine.”

- Standardize: Establish procedures and schedules to ensure repetition of the first three “S”s. Standardize the way you store files. Use OneDrive to store your working documents “not ready to share” and use SharePoint to store documents that should be shared with other team members.

- Sustain: Ensure the 5S approach is followed. Sustaining change is often the hardest part. After you decide on a schedule, mark the time on your Outlook calendar.

Not sure which storage solution is the right one for you? Check out our Understanding the difference between OneDrive, Teams, and SharePoint web page.

We all have customers, whether they be internal (faculty, students, staff) or external

(partners, vendors, colleagues) and we want to make them happy.

We all have customers, whether they be internal (faculty, students, staff) or external

(partners, vendors, colleagues) and we want to make them happy.

100% Effective has a great infographic about the three basics needs customers have – the delighters, the satisfiers, and the dissatisfiers.

Are you providing for all of your customer’s needs?

This time last year, the Lean team was in Ann Arbor, Michigan to attend the Lean HE

Conference. This was the first time it was held in the US and we met some awesome,

like-minded people and attended some really great sessions. This year, we’d hoped

to go to the conference in Australia. But, then COVID happened and changed everyone’s

world.

This time last year, the Lean team was in Ann Arbor, Michigan to attend the Lean HE

Conference. This was the first time it was held in the US and we met some awesome,

like-minded people and attended some really great sessions. This year, we’d hoped

to go to the conference in Australia. But, then COVID happened and changed everyone’s

world.

Adapting as lean people do, this year’s conference went virtual.

I’ll be the first to admit that I had a hard time adjusting to virtual meetings. It’s only recently that I’ve started to appreciate them for the added benefits.

If you haven’t considered how virtual meetings can be better than in-person meetings,

here’s an infographic to point out a few of the positives.

Ever wish you could have more insight into your work routine? Like how much time you had to really focus on tasks and how much time was spent collaborating with others? Could information like this help you be more productive?

MyAnalystics, a part of Microsoft 365, is an app that can track your daily work routine by looking at things such as time spent in meetings, reading Outlook emails, productivity and time spent working late.

Knowing your work productivity can help you work smarter instead of harder.

To get to MyAnalytics, open your favorite browser, go to https://portal.office.com/, and click the ![]() icon in the upper left corner. If you don’t see MyAnalytics listed, click All apps

on the left and search for it.

icon in the upper left corner. If you don’t see MyAnalytics listed, click All apps

on the left and search for it.

MyAnalystics tells you your work patterns from the last four weeks (at least mine does). You can change configurations by clicking on Config Settings on the bottom left.

While MyAnalytics is AI-driven and not 100% accurate, much like an Apple Watch, it can give you a good understanding of your daily routine, tell you who you have collaborated with and how much time was spent collaborating, and how all this can affect your daily wellbeing.

Learn more about MyAnalytics by clicking through this Microsoft Sway presentation.

We don’t actually hear people say it out loud, but we know they are thinking in the back of their minds, “Why should we care about Lean 6 Sigma?”

And, it is a valid question!

Lean 6 Sigma helps you look at your processes in a different way and streamline them. It can save you both time and money.

Oh, and did we mention it may help you get rid of pain points (parts of your job you dislike doing)?

Here are a few success stories GoLeanSixSigma has documented:

• Kern County reduced their hiring time by 37%

• UC San Diego’s Department of Strategic Initiatives Save 1,000 Hours a Yea in Employee

Onboarding

• US San Diego Saved $4 Million at Its Medical Center

• Child Support Services of Kern County Improved Its Help Desk Resolution Time by 64%

• The Nature Conservancy's Web Development Team Improved Operations by 95%

• Student Business Services Department at UC San Diego Reduced Student Mailing From

415 to 96 Minutes

We’ve had some successes here at UTHSC!

Our Lab Animal Care Unit (LACU) went through Lean training and using what they had learned, reduced wasted rodent food by simply using a smaller scoop. This change is projected to save them $71,000 a year. LACU also evaluated the frequency of bedding changes. This small change is projected to save $54,000 year.

Want to learn more? Check out our Lean UTHSC website or contact us at leancoach@uthsc.edu.

Since the start of the pandemic, many things in our personal lives have changed. I realize that is the understatement of the year but let’s think about food for a minute.

How many times did you order food for delivery before March? Personally, I don’t think I ever ordered delivery (unless you count pizza, of course!).

But, guess what? The pandemic made food delivery a common thing for many people. There are many food delivery services, but DoorDash has shined during this time and now owns 60% of the market. Sixty percent is huge! That only leaves 40% to be split among other companies like Uber Eats, GrubHub, Seamless, Postmates, and Eat24.

How did DoorDash do it?

- DoorDash quickly and continually gathered data from customers, restaurants, and drivers as soon as the pandemic hit and used that data to respond to needs in real time.

- DoorDash enabled their teams to make those changes swiftly and without a lot of bureaucracy.

- DoorDash immediately instituted such changes as no-contact delivery, tamper-proof packaging, and financial assistance to drivers diagnosed with COVID.

Customers, restaurants, and drivers noticed these changes and responded accordingly.

But, why am I talking about DoorDash? Because all of those things – gathering data, acting upon it quickly, and enabling teams to make their own decisions are all Lean qualities.

To learn more, listen to Qualtrics Co-Founder Ryan Smith as he presents Turning Working Differently into Working Better at the Work Different Conference.

Lean-minded folks often try to multi-task to increase productivity. “Maybe I’ll work on this Excel spreadsheet during this Zoom meeting and knock two things off my list at once!” Sounds super productive, right? It’s not.

Multitasking, also known as task-switching, actually kills productivity. Even simple things like checking emails during a meeting can divert your attention just enough to impair productivity. Plus, the switching back and forth is just fuel for creating errors.

With many people working from home right now, the challenges are even greater. Ever find yourself in a Zoom meeting, thinking about what you should cook for dinner while petting the dog on your lap? The struggle is real.

Instead of trying to multi-task, you can get more done by monotasking. It is just as it sounds – one task at a time. Monotasking lets you dig deeply into one task, so you give that task all your attention.

While this may be harder at home, doing things like having a designated office area and telling the kids you are “at work” and unless it is an emergency, you shouldn’t be disturbed should help. It may require more willpower than it would actually being in your office where you could shut the door and close off the world, but it can still be done.

Another tip for monotasking is to discover your peak performance time. I am a morning person and feel I am more alert then, but my husband does his best work at night. Working from home might allow you more flexibility to be able to focus in on one task when you are at your peak.

For more tips on monotasking, check out Monotasking Keeps the Brain Healthy and You More Productive from Inc.

Continuous improvement should never end. Life doesn’t quit changing – there’s always new thoughts, new technology, new challenges, etc. You should always be on the lookout for ways to be more efficient in your processes. Need help getting started? Here are a few steps:

- Better Planning. A project has to have a good foundation to grow properly. Do you know what the real problems are with the processes? If not, you may need to do a root cause analysis. Projects require people who can devote time on planning and who are invested in getting results from the project. Always have a project timeline with an end date in mind.

- Brainstorming. How do you get to the root cause of the problem? How can you improve the process? Brainstorming is one of the best ways to not only uncover the problem but begin to solve it. This includes bringing all who are involved in the process to the table to get multiple points of view. Including everyone helps foster collaboration and break down silos.

- Act Fast. Projects shouldn’t drag on and on unless you are looking into different aspects of the project. But some projects do take time. Quick wins, solutions you can implement quickly, are a great way to keep the team motivated and involved in the project.

- Track Results. You must do a baseline measure of your process to see if improvements offer any gain. You can track in numbers, time, or employee satisfaction. But you must measure the before the project starts then once changes are implemented, compare the two. If there are indeed improvements, you must work to keep those in place – don’t allow staff to fall back into the “old” way of doing things.

- Transform the culture. Continuous improvement should reach all aspects of your work. Abide by the first four steps will help change the work environment. Staff must feel empowered to help make changes. When they feel involved with the work, they often look in other areas for improvement, which results in a work culture change.

When the UTHSC Lean pilot program started in 2018, the object was to train all 70+ members of the ITS staff on the Lean 6 Sigma methodology and have each team complete a project. We quickly learned we had to bring in SMEs (subject matter experts) from other departments such as Facilities, HR, and Research to help with the projects. These trainings (developed and taught by BPS executive director Lisa Hall) lasted 12 weeks and covered all five phases of Lean 6 Sigma – Define, Measure, Analyze, Improve, and Control – in detail. You can learn more about the projects, team members, and improvements made on our Lean Success Stories webpage.

Those sessions were recorded and we have made them accessible on SharePoint. You will need to log in with your UTHSC NetID/password to access these.

If you’ve been through the one-hour BPM course (which is part of the Define phase), but would like to learn more about the different phases of Lean 6 Sigma, check these out! This is our first time making these available, so if you experience any problems, please let us know at leancoach@uthsc.edu.

I hope everyone is doing well during this crazy time! It’s definitely a different work environment, but I feel fortunate that technology allows many of us to continue business as usual (well, mostly).

Have you been a part of any Zoom meetings? Did you enjoy them or are you still learning your way around the app? Just this week, we added a Zoom webpage that might help you understand Zoom a bit better. If you haven’t had any Zoom meetings, but are interested in learning, check out the Zoom website. If you have any questions about Zoom or anything else, you can always reach out to appsupport@uthsc.edu or leancoach@uthsc.edu.

In the meantime, here’s a short (5-minute) video 3 Reminders About How to Hold a Great Virtual Meeting

If you are tired of bingeing Nexflix, give this video a look. The Lean Team got to see Bob Tipton speak at the SIM Memphis Strategy Series for Executives Conference last year and he was captivating. We think you’ll enjoy this video.

How is everyone doing with this new normal? It’s different, but hopefully you are settling in to a new daily process. That’s important during this time – to have a routine.

The Skimm wrote a great article about tips for working from home. You may have the physical things you need, like your laptop and software, but you may not think about the mental challenges that come with this new normal. Things like:

- Getting up at the same time, washing your face, showering, getting dressed

- Picking an “office” – a dedicated work space

- Setting office hours – make sure you log in and out of work at a regular time

- Scheduling breaks - getting up and moving every once in a while – it’s easy to get stuck in the new office for hours without moving

- Socializing – use Microsoft Teams or Zoom to talk to your coworkers and stay in touch, especially if you are home alone

Process out your new daily routine on a sheet of paper if you have to, just to help you keep on track until it becomes more normal.

ITS has a page devoted to Telecommuting and Remote Work resources. This is also a great opportunity to learn a new skill (if you have time) through LinkedIn Learning.

Stay safe!

In Lean 6 Sigma training, we use a quote from H. James Harrington: “Measurement is the first step that leads to control and eventually to improvement. If you can’t measure something, you can’t understand it. If you can’t understand it, you can’t control it. If you can’t control it, you can’t improve it.”

But we don’t want you to think, “I can’t measure this,” and give up.

GoLeanSixSigma just published a great article called 7 Ways to Measure & Manage Soft Skills. Take a look – it might help you figure out how to measure the seemingly “unmeasurable.”

While reading that article, it reminded me of a story Dr. Jeff Winer told our BPM class.

A hospital had a printer in a remote location. Residents complained about walking so far to get a printout, but the hospital’s reply was, “Sorry, the printer can’t be moved any closer.”

That is until someone decided to focus in on this pain point.

They determined the average time a resident spent walking to and from the printer.

They took the number of residents and came up with a total amount of time spent walking.

Then, they put that into a dollar amount – how much money it was costing to have residents walk back and forth.

After seeing this MEASUREMENT of how much MONEY the hospital was losing by having the printer in that location, the printer was moved.

Remember, your time is valuable and a good measurement to be used when trying to improve a process.

Alfred North Whitehead’s name doesn’t often pop up when you google Lean 6 Sigma pioneers.

That’s because he was an English mathematician and philosopher who was a defining

figure in process philosophy. Process philosophy “identifies the metaphysical reality

of change.” Deep, huh?

Whitehead lived from 1861 until 1947 and in that time, he wrote a lot about mathematics,

logic, and metaphysics – nothing I feel a particular kinship towards.

But the main reason I like Alfred North Whitehead is because of one of his quotes

I saw early in my Lean journey.

That quote really spoke to me. I printed it out about two years ago and it remains on my wall to this day.

As I say in our BPM class, humans are creatures of habit. We do something and do something and do something and rarely question why we do it. And, it seems to only get worse as we age.

Even as a lean coach, last week I had an “Ugh” moment. I’ve been working with a customer for 7 years and never asked her opinion about something. At the beginning of each month, I post her resident call schedules online. I usually schedule them to post at 5 am on the first day of the month. It never occurred to me to ask her the best time to post them, but last week, I decided to bring it up. I found out that posting the schedules at 12:01 am was better as some residents work at night and may be looking for the new schedules then. Why did it take me 7 years to learn this? Because I didn’t ask – asking what she wanted seems obvious, but I didn’t bother to analyze the obvious for a long time.

Have you ever had a new employee come into your office and question why you do something or offer a new way to do it? Did you feel offended? Don’t. Sometimes it takes a new set of eyes to question why something is occurring.

Change is hard, but change is also necessary to stay on the top of your work game. Lean 6 Sigma has tools to help make life easier:

- Question why you still do a step in your process? Business process mapping helps you examine your process in detail

- Need to identify your suppliers and customers? Complete a SIPOC

- Find out what your customers want. Send them a survey or do a focus group.

- Rearrange your office to put things you need closer to you. That’s the 5S methodology

Be that person that analyzes the obvious.

You’ve heard a picture is worth a thousand words, but have you ever thought about applying that to your work?

Here are a couple of examples of the same information in two different formats.

Example 1:

Last year, UTHSC awarded 1,047 degrees, which is higher than the last three years. Of those, 191 were professional, 152 were baccalaureate, 94 were doctoral, and 73 were masters. Most of the degrees awarded were in health professions, but we had a few in the biological sciences discipline. Our average GPA was 3.51.

Example 2:

Which one was easier and quicker to read? Most people would say the visuals of Example 2’s dashboard were easy to quickly scan and determine trends (such as a upswing for degrees awarded). This is a real example - the UT system has adopted data visualization. Visit https://data.tennessee.edu/ to see more.

Data visualization of your work is a great way to get your point across quickly. It can give you improved insight, help you make decisions faster, easily notice trends, and help convey your main points to others better than text.

One of the most important parts of Lean 6 Sigma is understanding what your customer truly wants. Not what we want, not what we think they want, but to have them tell us their expectations, preferences, and aversions. This is the Voice of the Customer (VOC).

Collecting the VOC can be done several ways – one-on-one sessions, group sessions, or surveys. Surveys are a great tool because you can reach a large audience and gather great metrics.

Here are a few tips to help you get the most out of your surveys:

- Identify what you want to cover in the survey: Think about the objective of the survey. What results do you really want to capture? Unfortunately, we’ve learned this the hard way. We’ve gotten survey answers we really couldn’t use. An example is when we asked the UTHSC faculty and staff the last time they had UPDATED their personal or work information. We were shocked to get so many “over 5 years ago” responses. Then, we realized we asked the wrong question. What we really wanted to know was the last time they CHECKED their personal and work information for accuracy. Those that replied “over 5 years ago” may have checked their information recently but didn’t update it because nothing had changed.

- Put questions that are necessary: Only ask what you need to know. For example, if age won’t make any difference in the survey, don’t ask for it. And keep your survey objective in mind while coming up with questions.

- Keep it short and simple: Nothing is worse than going into a survey and after about 10 questions, you think, “Is this ever going to end?” Don’t assume that if people start the survey, they will finish it. In the opening paragraph, let them know the survey will only take X amount of time or consists of X number of questions.

- Ask one question at a time: A question like, “How often do you use this software and what do you like about it?” won’t give you helpful results. One question at a time, please.

- Avoid using jargon: We love our acronyms in higher ed, but don’t assume everyone know what IRIS is or what OED stands for. Use language that is easy-to-understand to ensure your respondents finish up the survey.

- Open-ended or closed-ended questions?: An open-ended questions is like an essay question on a quiz – the respondent can type whatever they want as an answer. A close-ended question is the opposite – it has pre-defined responses the respondent selects. So, which one do you use? It’s probably good to have a mixture. A pro of an open-ended question is you get how the person feels in their words. A con of an open-ended question is two people my essentially say the same thing, but you have to manually collate similar replies to get any type of metrics. A con of close-ended question is you may not have given all the potential answers. A pro of a close-ended question is you’ll get great metrics.

- Spend time to design your survey: Don’t spend five minutes coming up with questions and send the survey immediately. Wait 24-hours then look at the questions again. Ask yourself the questions and see if your answers are ones you were really hoping to get. Have others look at your questions.

- Analyze the responses after collecting: Our survey software (QuestionPro and Qualtrics) will give you a spreadsheet of all the responses. Look at your answers and try to get metrics.

- Put a summary report together: This step is easy – QuestionPro and Qualtrics will create a report for you that you can share with others.

- Conclude your plan of action: Look at the survey results, determine what they told you and draw a conclusion. If you are trying to improve a process, this is your baseline. After you’ve made changes, send the same survey questions again to see if your changes made any difference.

Curious about sending surveys? Visit our Application Support website for more information about our survey software or contact the Application Support team at appsupport@uthsc.edu.

The 5 Whys is an awesome tool to help you understand the root cause of a problem. And, it’s as easy as it sounds. Ask “Why?” something is happening then ask “Why?” again and again and again.

Have you ever seen a young child ask a question? They usually don’t stop after they get the first answer. They keep asking “Why?” until they feel they have a true understanding of something. As we age, we lose that child-like curiosity, but it’s a great thing to re-learn.

5 Whys and the Jefferson Memorial

Several years ago, park rangers noticed the stone was deteriorating on the Jefferson Memorial and asked why.

They were told the staff cleans the monument every two weeks.

The park rangers could have stopped there. They could have rushed into “problem-solving mode” – something many of us do by habit. They could have thought, “Well, it is an outdoor monument, exposed to the elements, so that makes sense” and maybe switched to a different type of cleaner. Or, they could have changed the cleaning to every four week and just had a dirtier, yet potentially more stable monument. Or, maybe they could have even organized a committee to talk about an eventual replacement of the monument. After all, nothing lasts forever.

Instead, they asked why is it cleaned every two weeks.

Because of all the bird poo.

Ah, so the park rangers put up nets to keep the birds off the monument. Sure, it made the monument a bit unsightly, but if it fixes the problem…

It didn’t. The birds were able to get through the nets and continue to poo on the monument.

So, the park rangers asked why there were so many birds at the memorial. The answer was because they were feasting on the spiders that live in the memorial.

That makes sense! The birds are just hungry! But, why does the monument have so many spiders?

The spiders like to eat the flying insects the monument attracts.

Well, why do we have so many flying insects at the monument?

They are attracted by the spotlights turned on every night to illuminate the monument.

After delving into the problem, the park rangers decided to delay the spotlights to one hour after sunset.

That simple solution led to 90% fewer insects, which led to fewer spiders, fewer birds, and fewer cleanings.

So next time something is not quite right at work, as yourself “Why?” a few times to dig to the heart of the problem.

(special thanks for Dr. Jeff Winer for bringing this excellent 5 Whys example to our attention!)

What is 5S?

5S is a Japanese method to organize your workplace. The 5Ss are seiri, seiton, seisō, seiketsu and shitsuke. These have been translated into:

- Sort: Sort through the items around you and remove anything unnecessary.

Ever look around your workplace and see something you don’t use anymore? Do you ever take time to sort through items in your workplace to get rid of unnecessary clutter? Getting rid of stuff you don’t need makes it easier to find stuff you do need! - Set in Order: Put all necessary items in the optimal place.

Put things you use constantly closest to you. The less you use something, the further away it should be. - Shine: Sweep, clean, and inspect workplace tools and machinery on a regular basis.

Our office supplies cabinet was a mess at one point. Then, our administrative staff decided to take everything out and organize it. It’s much easier to find things now! Cleaning and inspecting workplace tools on a regular basis may also help ensure they are in working order. - Standardize: Establish procedures and schedules to ensure repetition of the first

three “S”s.

The first three “S”s seem easy, but the fourth – standardize – may take some time to sink in. You can’t sort, set in order, and shine once and stop – you need a schedule of when these should occur. Everyone should know their part for sorting, setting in order, and shining. Visual representation, such as photos, is a great way to help keep everything as it should be. - Sustain: Ensure the 5S approach is followed.

Sustaining change is often the hardest part. Sustain often goes hand-in-hand with self-discipline as it takes discipline to make sure the first 4 “S”s are continued over time. Create new daily habits that help you keep organized like taking the first 10 minutes of the day to clean out old emails or the last 10 minutes of the day to straighten your desk.

Our work and personal lives are made up of processes. It can be things you do daily (wake up, make coffee, eat breakfast), or weekly (Monday night laundry, Tuesday night soccer practice, Friday night date night) or even yearly (March pay taxes, June vacation, September start Christmas shopping). It is basically your routine, what steps you take to complete things.

A process map is a visual representation of a process. A process map can show you interacting with people (manager, co-workers) or things (databases, paper forms). A process can show you making a decision and what steps to take afterward (Did the employee fill out all the fields on the form? Yes, go to next step. No, return until all fields are completed).

Why would you want to map out your process? Because when we see our process in black and white, we begin to understand it better.

A process map can help you figure out who are the suppliers, inputs, outputs, and customers in your process. Areas that cause you pain (pain points and bottlenecks) and areas of opportunities start to appear so you can begin to brainstorm ways to improve. If you don’t know why you do something in your process, ask yourself why. Why do we send that form to the manager to be signed? If the answer is “Because we’ve always done it that way.” that’s not a good enough reason. Ask the manager if he or she wants to sign or even see that form. If the answer is no, you’ve improved your process by saving yourself a unnecessary step (and saved your manager time as well!).

Mapping your work processes can help you look at what you do differently. It can improve

your productivity and increase communication between you and co-workers or others

at the university. It can also be used as a training tool for new hires.

Sometimes when people think about Lean, they think it refers more to manufacturing.

Sometimes when people think about Lean, they think it refers more to manufacturing.

But, waste can occur anywhere – especially in higher ed. Look closely at your daily or weekly processes.

Do you:

- have someone sign a form just because it’s always been done that way?

- have a form that has fields that you never use, but no one ever updated it?

- find yourself with an abundance of office supplies that you’ll never use?

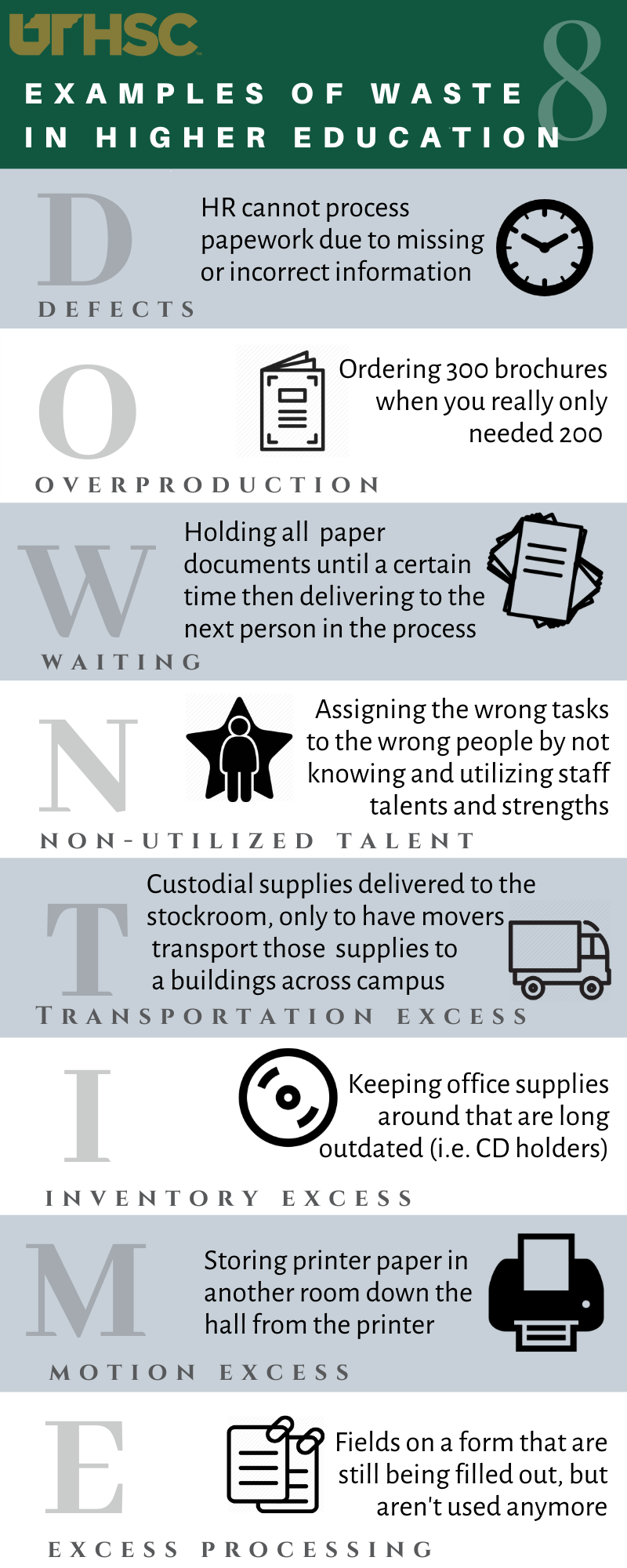

Here’s an infographic with some examples of DOWNTIME.

Waste can waste a lot of your time, but first, you must recognize it as waste.

Remember the words of Alfred North Whitehead – “Familiar things happen, and mankind does not bother about them. It requires a very unusual mind to undertake the analysis of the obvious.” It’s almost a new month, new year, and new decade, so making resolutions may be on

your mind.

It’s almost a new month, new year, and new decade, so making resolutions may be on

your mind.

Many of us think about resolutions like going to the gym or eating healthier but remember that a new year can also mean a new start by taking a closer look at your job duties.

Here are a few steps to help get started:

- Focus on the customer. Remember the old saying, “The customer is always right?” Be sure to listen to your customers. Sometimes, we think we know what the customer wants when we really don’t! Make 2020 the year to do a little Voice of the Customer (VOC) research. This can be done one-on-one for a more personal touch or, if you have many customers, you can send a Qualtrics/QuestionPro survey asking them what they like, don’t like, would like to see done, etc. Don’t know how to use QuestionPro/Qualtrics? Contact Application Support at appsupport@uthsc.edu.

- Understand your work. Process mapping is an excellent way to document the flow of your work. And, it’s super easy to do – you can start by simply writing down the steps you take to get certain tasks done. It not only helps others understand what you do, but it also lets you take a good look at your process to determine if there’s anything that can be cut out (waste). Also, having documentation of your process is useful when onboarding new employees!

- Communicate! We’ve found in working with some groups that they share information with other areas – yet the two never talk to each other! Don’t ignore the prospect of getting together cross-functional teams to share information, processes, and even brainstorm a better way to do things. When we’ve brought groups together, ideas of how to improve their processes just naturally occur once they start talking. Not sure how to get started? Contact Lisa Hall at lhall37@uthsc.edu.

A new year is a great time to start implementing Lean thinking to help you improve your work.

Happy New Year!

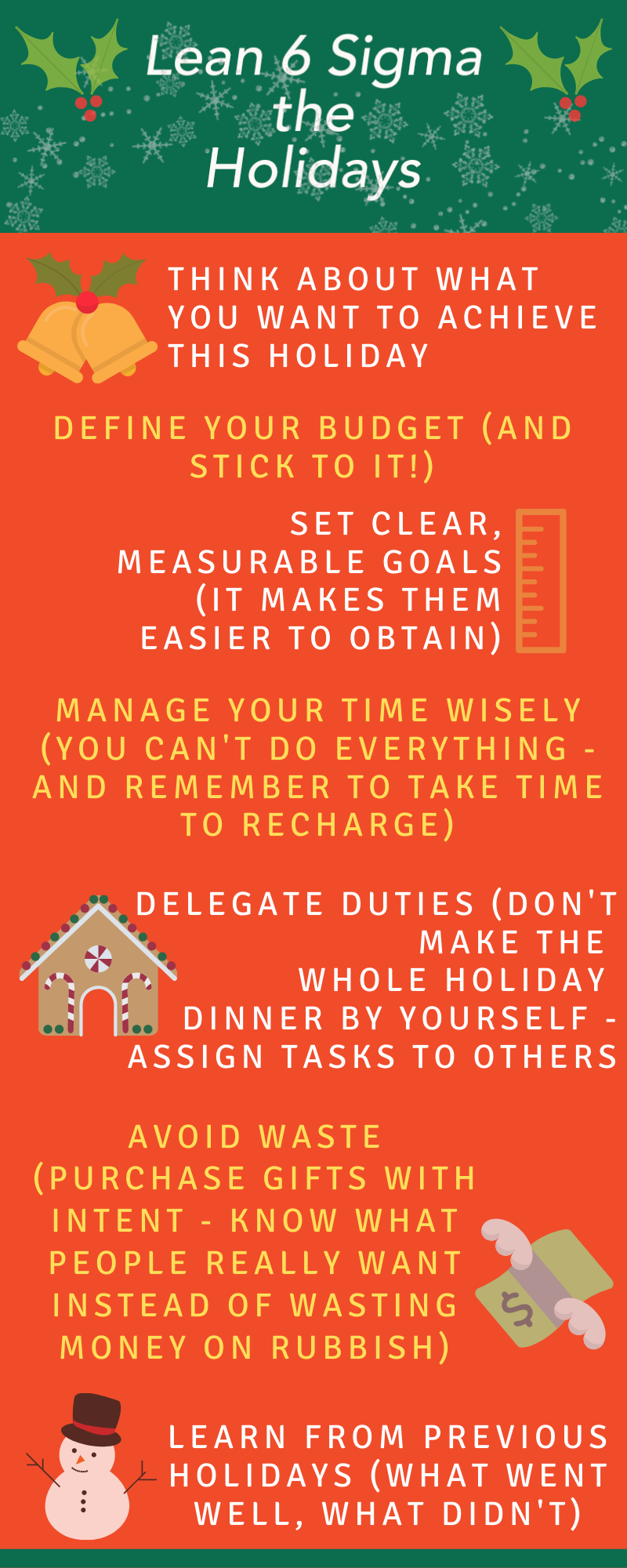

The holidays can be a stressful time, but did you know you can make it easier by applying

Lean tips? Lean isn’t just for work – it can help you keep your personal life in

order, too!

The holidays can be a stressful time, but did you know you can make it easier by applying

Lean tips? Lean isn’t just for work – it can help you keep your personal life in

order, too!

- Think about what you want to achieve this holiday

- Define your budget (and stick to it!)

- Set clear, measurable goals (it makes it easier to obtain them)

- Manage your time wisely (you can’t do everything – and remember to take time to recharge)

- Delegate duties (don’t make the whole holiday dinner by yourself – assign tasks to others)

- Avoid waste (purchase gifts with intent – know what people really want instead of wasting money on rubbish)

- Learn from previous holidays (what went well, what didn’t)

And, use lists (for mailing cards, attending events, food preparation) and your calendar to keep you organized.

If you need a visual to help you keep on track, take a look at this infographic!